Introduction

Fire safety is one of the most critical aspects of building design, industrial operations, and community planning. At the heart of effective fire protection systems lies the fire pump, a device designed to provide high-pressure water flow whenever an emergency occurs. Without reliable pumps, sprinkler systems, hydrants, and suppression equipment cannot perform their life-saving roles.

This article explores the role of pumps in fire protection systems, the different types used, safety standards that govern them, and best practices for installation and maintenance.

Importance of Pumps in Fire Protection

Fire pumps ensure that water is delivered at the correct pressure and volume to extinguish or control a fire. In many cases, municipal water supplies do not have enough pressure to support large sprinkler systems, making pumps a vital component.

- Boosting water pressure: Ensures sprinklers and hydrants operate effectively.

- Ensuring reliability: Fire pumps are designed to run immediately when activated, even under emergency conditions.

- Supporting large buildings: High-rise buildings, warehouses, and industrial facilities rely heavily on fire pumps.

Types of Fire Pumps

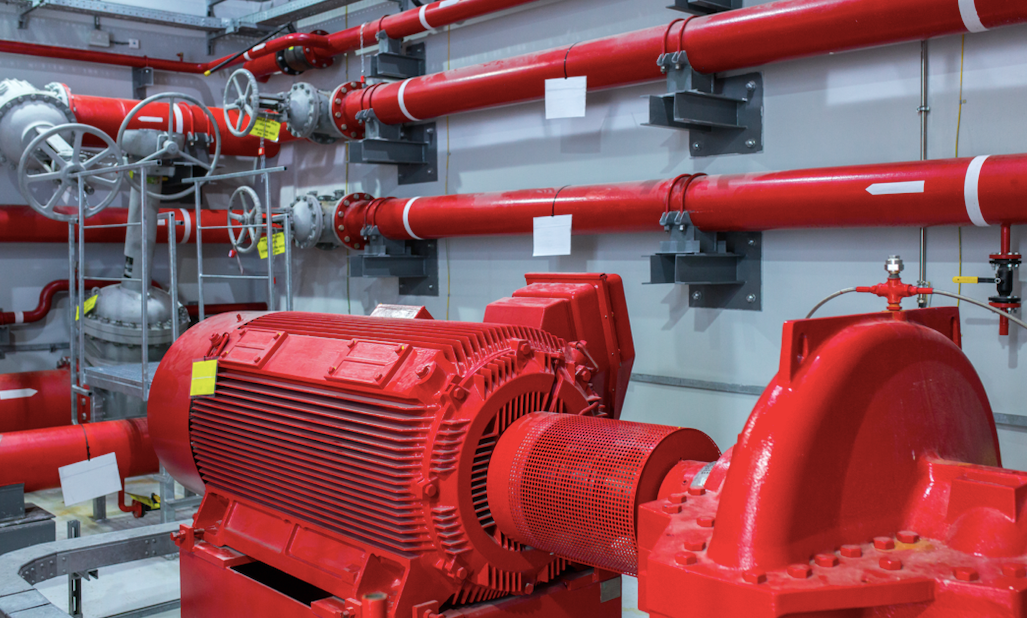

Centrifugal Fire Pumps

The most common type, centrifugal fire pumps deliver steady water flow at high pressure. They are widely used in sprinkler and hydrant systems.

Vertical Turbine Fire Pumps

Ideal for locations where water comes from reservoirs, tanks, or underground wells. They lift water vertically and supply it to the system.

Horizontal Split-Case Fire Pumps

Known for their durability and ease of maintenance. Common in large facilities requiring high flow rates.

End Suction Fire Pumps

Compact and cost-effective, often used in smaller systems with limited space.

Positive Displacement Fire Pumps

Used in special applications where water supply needs to remain constant, such as foam systems.

Fire Pump Activation Methods

Automatic Activation

Fire pumps start automatically when system pressure drops (e.g., when a sprinkler opens).

Manual Activation

Operators can manually start pumps if needed during emergencies.

Diesel and Electric Options

- Electric pumps: Depend on power supply, often backed by generators.

- Diesel-driven pumps: Provide reliability when electricity is unavailable.

Fire Pump Safety Standards

Fire pump installation and operation are governed by strict international and local standards to ensure reliability.

NFPA 20 (National Fire Protection Association)

One of the most widely adopted standards worldwide. It covers design, installation, testing, and maintenance of fire pumps.

UL and FM Approvals

Pumps must be tested and certified by recognized organizations like UL (Underwriters Laboratories) or FM Global to ensure safety.

Local Building Codes

Municipalities often require compliance with regional regulations for fire protection systems.

Installation Considerations

- Water supply reliability: Pumps must be connected to dependable sources like reservoirs or municipal lines.

- Location of pumps: Fire pump rooms must be accessible, ventilated, and protected against flooding or fire hazards.

- Backup systems: Facilities often include diesel backup pumps or multiple pumps for redundancy.

Maintenance of Fire Pumps

Regular inspection and testing are critical to ensure fire pumps are ready for emergencies.

- Weekly churn tests: Running the pump without water flow to confirm operability.

- Annual flow tests: Measuring performance under full load.

- Component inspections: Checking seals, bearings, alignment, and lubrication.

- Battery and fuel checks: Essential for diesel-driven pumps.

Challenges in Fire Pump Systems

- Power failures: Without backup, electric pumps may fail during outages.

- Improper sizing: Pumps that are too small or too large can compromise performance.

- Neglected maintenance: In emergencies, neglected pumps may not function properly.

Conclusion

Fire pumps are indispensable for building and industrial safety. By ensuring sufficient water pressure, they allow sprinkler and hydrant systems to perform effectively. Adhering to safety standards such as NFPA 20 and conducting routine maintenance ensures that pumps remain reliable when lives and property depend on them.

Investing in proper fire pump systems is not just a compliance requirement—it is a vital step toward ensuring safety and peace of mind.

FAQs

Q1: Do all buildings need fire pumps?

Not all. Smaller buildings with adequate municipal water pressure may not need them, but larger facilities almost always require fire pumps.

Q2: How often should fire pumps be tested?

Weekly churn tests and annual flow tests are recommended by NFPA 25 to ensure functionality.

Q3: Can a fire pump run dry?

No. Fire pumps must always have a reliable water source to avoid damage and ensure performance.

Q4: Which is better: diesel or electric fire pumps?

Electric pumps are easier to maintain but rely on electricity. Diesel pumps provide reliability in case of power outages.

Q5: What happens if a fire pump fails during a fire?

It can significantly reduce system performance, potentially leading to uncontrolled fire spread. Backup systems are recommended to avoid this risk.